We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

From the precision of Aston Martin Formula One Team to the stringent requirements of HS2 and Hinkley Point C, our operations and health and safety teams work closely together to provide a seamless and safe working environment for everyone.

We deliver using our own fleet of vehicles and use our well-trained rigging teams to build every structure. Our list of accreditations demonstrates the level of commitment we devote to staff, client and public welfare around our structures and build sites.

From our overall policies to method statements for different structure types, risk assessments for all activities and documented inspection systems of our equipment, you can be sure that our tried and tested systems can be relied upon.

All of our structures conform to wind loading stipulations (BS6399) and special care is taken by us to heat structures in winter, to prevent build up of snow on the roofs of our structures.

The materials used in our structures are fire retardant to current British Standards (PVC flammability testing to BS7837) – Structural steelwork conforms to BS5950 and structural aluminium to BS8118. Linings are flammability tested to BS5867 and all electrical equipment is Portable Appliance Tested (PAT tested) annually.

Fews staff are amongst the most experienced, well trained and qualified in our industry.

We invest heavily in gaining the accreditations that allow us to work in the most challenging conditions, and this extends to all Fews employees and contractors.

Every person has a personal training plan designed to ensure that they have the necessary skills to complete their work in the most efficient and safe way possible.

Our comprehensive training matrix ensures that all our personnel from Senior Management through to office staff and marquee riggers receive the very best training available.

This is a very fluid part of our Health and Safety training and Fews are always looking at ways to improve the skill base of their workforce. Our continuous improvement philosophy is ingrained in all our staff

Constructing temporary buildings on operational sites requires a skilled workforce with specific qualifications. We provide a tailored service to such sites to make sure that all construction works are isolated and the public is safe. It is of critical importance that we reduce the risk of injury to the lowest possible levels to minimise your liability and protect all stakeholders. You can trust us, and this is why:

Maintaining high professional standards is fundamental to the Fews approach. We have many health and safety, process and environmental accreditations including CHAS Elite, SafeContractor, Constructionline Silver, ISO9001 and ISO14001.

All personnel involved in the construction process must undergo Disclosure and Barring Service (DBS) checks to ensure a safe and secure working environment in proximity to the public.

The ability to deliver materials outside of regular hours is essential to minimise disruptions to the ongoing educational activities and ensure the safety of the public and staff alike. This requires coordination and planning to ensure a seamless construction process.

There are a number of essential accreditations that are required to work in any environment. Fews also operate on numerous nuclear sites which means a much higher level of training and accreditation. There is more information on our accreditations and training programmes.

All of our site staff wear branded hi-viz clothing and all of our vehicles are clearly branded for easy identification to ensure the safety of the public and staff.

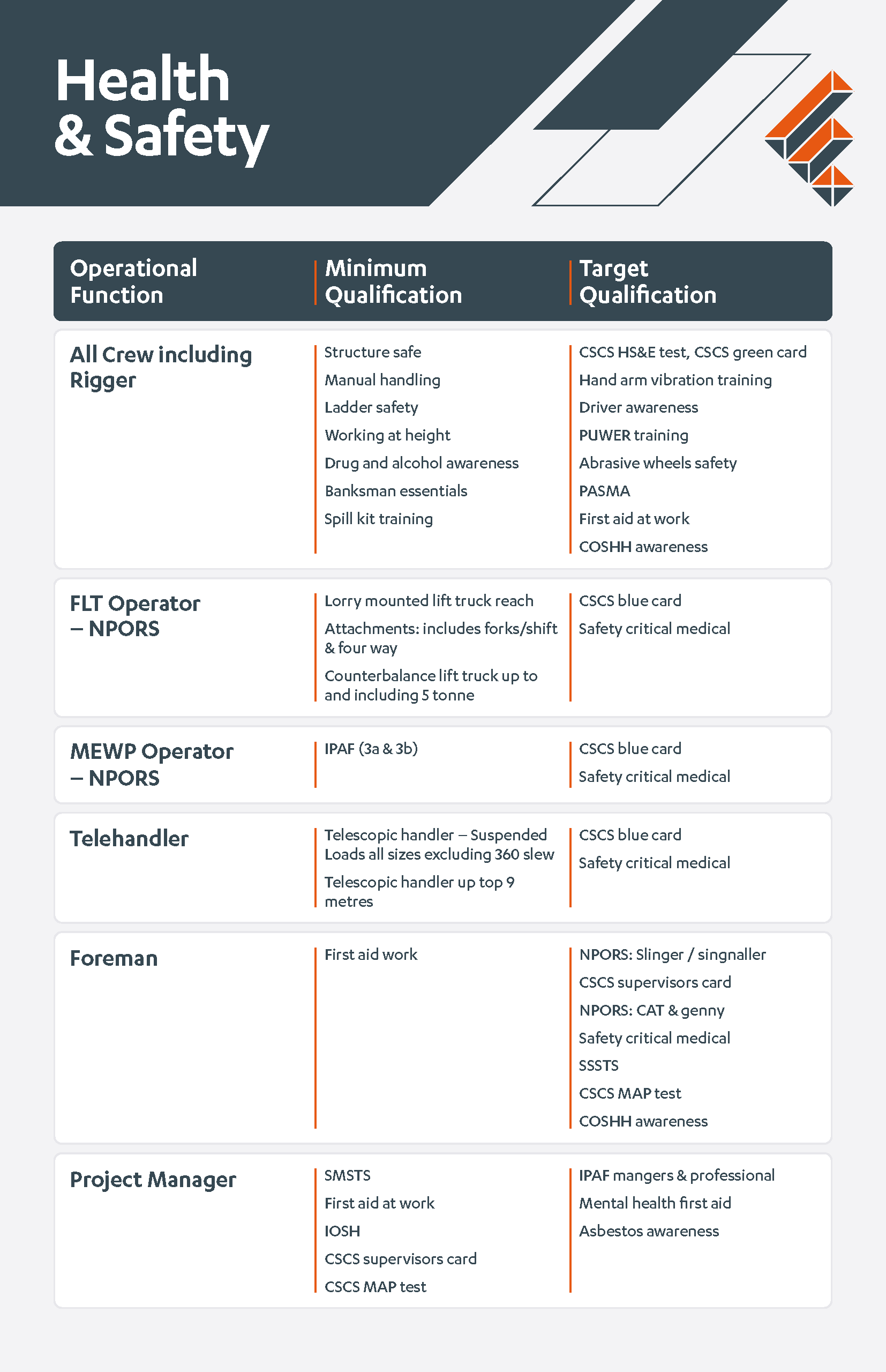

Fews always ensure that all workers employed in any location on their behalf will be suitably qualified in line with the requirements of the site. In addition, we ensure that they will be competent at the tasks that they are required to undertake. The matrix below shows the minimum levels that our on-site crew must attain, and the ambitions of Fews for them to achieve in the future. In many cases the ambitions have already been achieved. This clearly demonstrates how Fews are able to operate on some of the most sensitive sites in the UK.

All office staff undergo regular training in role specific courses and general H&S related competences including:

All of our yard and warehouse personnel undergo training in these areas, as well as more role specific courses:

Call 01527 821789 or email info@fews.co.uk

Matt, Molly, Lucy and Jack are our dedicated commercial team with extensive expertise and experience designing event solutions. One of them will guide you through every step of the process.

Request a Quote